We get it. We truly do. There is something primal and satisfying about walking through the aisles of a hardware store, smelling the sawdust, and loading up a cart with 2x4s and plywood. The “Weekend Warrior” spirit is alive and well, and the idea of building your own custom outdoor TV cabinet for a fraction of the retail price is incredibly tempting.

A quick search for “how to build an outdoor tv cabinet” yields thousands of results—rustic designs, barn-door styles, and clever hidden mechanisms. It looks like a fun project. A few cuts, some screws, a coat of varnish, and you’re done, right?

Here is the sympathetic but blunt truth: Protecting a $500 delicate electronic device is fundamentally different from building a planter box or a pergola. When you build a wooden box for a TV, you are fighting against thermodynamics, biology, and chemistry.

While a DIY approach feels like it saves money upfront, the “hidden taxes” of weight, heat retention, and material degradation often mean you spend $350 and two weekends to build a device that slowly cooks your TV. An engineered polycarbonate enclosure solves the fatal flaws of Heat Trapping, Structural Weight, and Moisture Warping for a similar total cost, without the risk.

Last Updated: Dec 31th. 2025 | Estimated Reading Time: 9 Minutes

The “Heat Trap”: Why Wood is the Wrong Material

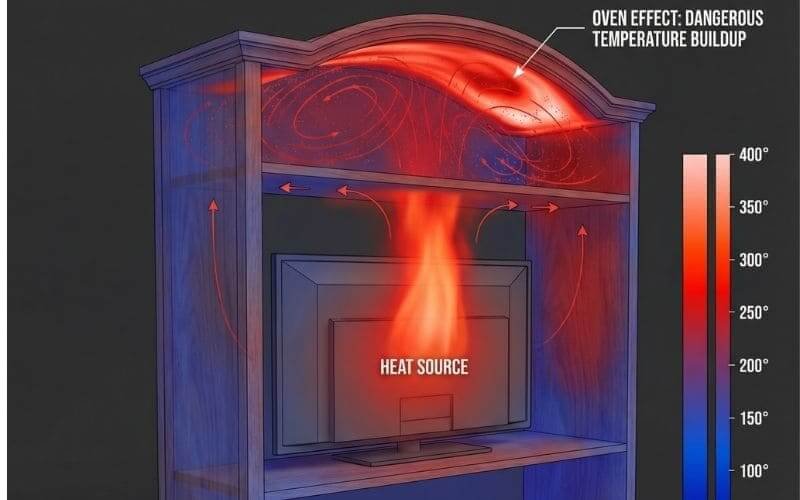

The Engineering Verdict: Wood is a natural thermal insulator with an R-Value of roughly 1.4 per inch. It is biologically designed to keep heat in. By enclosing a TV in wood without active, pressurized cooling, you are essentially placing your electronics inside a kiln, drastically accelerating component failure.

If you are a builder or a homeowner, you know that insulation is good. You want your house walls to hold heat in during winter and keep it out during summer. Wood does this naturally because its cellular structure is filled with air pockets. This makes it a fantastic material for framing a house.

However, this same property makes it catastrophic for an electronic enclosure.

The “Capacitor Death” Scenario: The Chemistry of Failure

To understand why heat matters, we have to look inside the TV at the motherboard and power supply unit (PSU). These boards are populated with Electrolytic Capacitors—those little cylinders that look like batteries. Inside these capacitors is a liquid electrolyte that allows them to store and regulate energy.

In engineering, we follow a rule of thumb derived from the Arrhenius Equation: For every 10°C (18°F) rise in operating temperature, the life expectancy of a capacitor is cut by 50%.

When you run a 4K TV, the backlight array and the image processors generate a significant amount of heat—often 150 to 200 watts. Inside an Outvion enclosure, the thin polycarbonate walls allow some conductive heat transfer, but more importantly, the active fans strip that heat away. Inside a 3/4-inch plywood box, that heat is trapped. The wood acts as a thermal blanket.

- The Scenario: It is a 90°F (32°C) day. Inside your wooden box, the ambient air quickly rises to 130°F (54°C). The internal temperature of the TV components hits 175°F (80°C).

- The Result: The liquid electrolyte inside the capacitors begins to evaporate and expand. Eventually, the capacitor bulges and leaks, or simply dries out. The TV won’t turn on. You haven’t “burned” the TV in a fire; you have chemically aged it 10 years in a single summer.

The “Passive Venting” Myth

The most common counter-argument I hear from DIYers is: “I’ll just drill some holes in the back. Heat rises, right?”

This demonstrates a misunderstanding of fluid dynamics. Yes, hot air rises (convection). However, for hot air to leave the box through top vents, an equal amount of cool air must enter from the bottom to replace it. In a densely packed wooden box with a large TV blocking the airflow path, natural convection is too weak to overcome the static pressure. You create a “heat soak” condition.

Furthermore, drilling holes destroys your weatherproofing. You are inviting humidity and wasps in, hoping that heat will find its way out. It is a losing trade.

The Outvion Difference: We rely on Forced Convection. Our fans are rated for specific CFM (Cubic Feet per Minute) throughput. We calculate the volume of the enclosure and ensure that the air is completely replaced every 15-20 seconds. We don’t hope the heat leaves; we physically grab it and throw it out.

A Real-World Horror Story

I once consulted for a homeowner in Phoenix, Arizona. He had built a stunning cabinet out of reclaimed barn wood. It looked beautiful. One July afternoon, he turned the TV on, and the image looked warped. When we opened the cabinet, the heat buildup had been so intense that the black plastic bezel of the TV frame had actually softened and warped, pulling away from the glass screen. The wood felt hot to the touch on the outside. The TV was a total loss.

Material Physics Comparison (Wood vs. Polycarbonate)

| Feature | DIY Wood Cabinet (Plywood/Pine) | Outvion Enclosure (Polycarbonate) |

|---|---|---|

| Thermal Properties | Insulator (Traps heat like a blanket) | Conductor (Thin walls shed heat) |

| Moisture Reaction | Hygroscopic (Absorbs water, swells) | Hydrophobic (Repels water, stable) |

| Dimensional Stability | Warps/Twists with seasons | Stable from -22°F to 122°F |

| Combustibility | High (It’s wood) | Flame Retardant (Self-extinguishing) |

The Weight & Mounting Nightmare

The Engineering Verdict: A DIY wood cabinet often weighs 3x more than an Outvion unit and extends significantly further from the wall. This depth creates a dangerous “Moment Arm,” multiplying the pull-out force on your anchors and creating a risk of catastrophic structural failure.

When you hold a piece of paper, it’s light. When you hold a sledgehammer at the end of the handle, it’s heavy. This is the physics of leverage, and it is the enemy of the DIY cabinet builder.

The Physics of the “Moment Arm”

Weight isn’t just about gravity pulling straight down (Shear Force). It is about the leverage pulling away from the wall (Tension).

- The DIY Dimensions: To fit a TV inside a wooden box with 2×4 framing, the cabinet usually ends up being 8 to 10 inches (20-25cm) deep.

- The Outvion Dimensions: Our enclosure is engineered to be slim—roughly 4 to 5 inches (10-12cm) deep.

Because the center of gravity in a DIY box is much further from the wall, the “Moment Arm” is longer. A 100lb wooden cabinet protruding 10 inches exerts significantly more tension on the top mounting screws than a 40lb Outvion unit protruding 4 inches. You aren’t just hanging a picture; you are hanging a cantilevered load. If you are mounting into vinyl siding or old brick, the risk of the top anchors ripping out—sending the cabinet crashing down onto your patio pavers (or a pet)—is a mathematical reality you must calculate.

The Hidden Chemical Danger: Galvanic Corrosion

This is a “Pro Tip” that few DIYers know, and it causes decks and cabinets to collapse every year.

If you are building for the outdoors, you naturally reach for Pressure Treated Lumber (the green-tinted wood) because it resists rot. In the US and many parts of Europe, this wood is treated with ACQ (Alkaline Copper Quaternary).

- The Chemistry: ACQ contains high concentrations of Copper.

- The Reaction: If you use standard aluminum brackets, generic steel screws, or even some grades of galvanized hardware, you create a battery. The copper in the wood reacts with the zinc or steel in the screw in the presence of moisture. This is Galvanic Corrosion.

- The Failure: The copper eats the screw. I have seen cabinets that looked solid on the outside, but the screws holding them to the wall had dissolved into rusty dust inside the wood. One day, gravity wins, and the cabinet falls.

To build safely with pressure-treated wood, you must use expensive double-hot-dipped galvanized or 305/316 Stainless Steel hardware. Most DIYers skip this to save money, unknowingly building a time bomb. Outvion enclosures use powder-coated steel and stainless hardware that is chemically inert—no corrosion, no surprises.

Water & Bugs: The Impossible Seal

Wood is hygroscopic, meaning it constantly absorbs and releases moisture, causing it to expand and shrink. This dynamic movement inevitably breaks static seals like caulk or paint, opening the door for moisture ingress, mold, and insect infestation.

You can paint wood. You can varnish it. You can slather it in marine sealant. But you cannot stop it from being wood. Wood was once a living vascular system designed to transport water. It never loses that thirst.

The Timeline of Decay

Let’s look at the lifecycle of a typical DIY outdoor TV cabinet to understand why they fail.

- Month 1 (The Honeymoon): You finish the build. The paint is fresh, the silicone beads are tight, and the cabinet looks secure. You feel like a genius for saving money.

- Month 6 (The First Season Change): Winter arrives (or a dry spell in Australia). The humidity drops. The wood fibers contract. The cabinet shrinks slightly. The silicone caulk you applied does not shrink at the same rate. Micro-fractures appear at the joints where the plywood meets the 2×4 frame. You can’t see them with the naked eye, but they are there.

- Month 12 (The Humidity Bomb): Summer returns. High humidity. Moisture enters through the micro-fractures. Because the wood is painted on the outside, the moisture gets trapped inside the wood. The interior of the cabinet becomes damp. Mold spores begin to grow on the felt lining or the drywall backing you used.

- Year 2 (The Failure): The damp environment inside the box has facilitated “dendritic growth” on the TV’s circuit boards—metallic crystals that grow between contacts. One day, you turn the TV on, hear a pop, and smell ozone. The TV is dead.

The Bug Psychology: Why Ants Love TVs

It’s not just water. It’s biology. Insects, particularly ants and wasps, are attracted to two things: heat and electromagnetic fields (EMF).

A TV in “Standby” mode generates a faint hum and a localized heat spot. To a foraging ant scout, this signals a perfect nesting site.

- The Breach: Remember those micro-fractures in the wood? That is the front door.

- The Colony: Once one ant finds the warm, dry space inside your DIY cabinet, they lay a pheromone trail. Within days, you can have a colony moving in.

- The Damage: Ants often build nests using damp soil or chew through thermal paste. Their bodies can bridge electrical contacts, causing short circuits. I have opened DIY wooden cabinets to find the entire power supply unit caked in mud and ant larvae.

An Outvion enclosure uses compression gaskets and micromesh filters. It creates a hermetic seal against biology. It doesn’t rely on caulk; it relies on mechanical pressure that ants cannot chew through.

The “True Cost” Breakdown (TCO Analysis)

This is usually the deciding factor. You assume DIY is cheaper. But let’s look at the receipts. If you build a cabinet properly—using rot-resistant wood, proper outdoor-rated hardware, and legitimate weatherproofing—the savings evaporate.

The True Cost Breakdown (Est. for 55″ Unit)

| Component | DIY Project Cost (Estimate) | Outvion Enclosure Cost |

|---|---|---|

| Lumber & Materials | $120 (Cedar/Marine Ply + 2x4s) | Included (Polymer Frame) |

| Front Panel | $80 (Thick Plexiglass/Acrylic sheet) | Included (UV Polycarbonate) |

| Weatherproofing | $40 (Ext. Paint, Stain, Caulk) | Included (Powder Coated) |

| Mounting Hardware | $60 (Heavy duty mount + Lag bolts) | Included (Internal VESA Mount) |

| Cooling System | $30 (USB Fans + Wiring kit) | Included (Thermostatic Fans) |

| Miscellaneous | $20 (Hinges, Handles, Locks) | Included (Dual Locks) |

| Your Time | 10-15 Hours (2 Weekends) | 45 Minutes Install |

| TOTAL | $350.00 + Stress & Labor | ~$450.00 (Peace of Mind) |

The Verdict: For a difference of roughly $100, you’re trading 20 hours of labor and a high risk of failure for a 45-minute guaranteed solution. Is your weekend really worth less than $5 an hour?

Aesthetics: The “Box on the Wall” vs. Premium Fixture

DIY cabinets typically add significant visual bulk, protruding deep into the living space and creating a “coffin-like” aesthetic. Furthermore, the maintenance requirement of staining and painting wood contradicts the modern trend of low-maintenance “Outdoor Living Rooms.”

We are living in the golden age of the “Outdoor Living Room.” Homeowners are spending tens of thousands of dollars on teak furniture, composite decking, sleek fire tables, and architectural lighting. The goal is to make the patio feel as high-end as the indoor lounge.

The “Coffin” Effect

In this sleek environment, a DIY wooden TV cabinet sticks out—literally and figuratively. Because of the structural requirements of wood (using 2x4s and 3/4″ ply), it is almost impossible to build a wooden cabinet thinner than 8 inches.

- The Profile: When you hang an 8-inch deep box on the wall, it dominates the space. It casts long shadows. From the side, it looks like a shipping crate or, as many unhappy spouses have noted, a “coffin on the wall.”

- The Outvion Profile: Our engineers fight for every millimeter. By using high-strength polymers structures, we reduce the Z-depth (thickness) to barely 5 inches. The unit hugs the wall. The matte black powder-coat finish is designed to absorb light, not reflect it, allowing the TV to disappear into the décor when not in use.

The Maintenance Trap

Finally, consider the value of your time.

- The Wood Reality: Outdoor wood turns gray. UV rays strip varnish. Rain peels paint. To keep a DIY cabinet looking good, you must sand and restain it every 1 to 2 years. If you don’t, it becomes an eyesore—a rotting grey box dripping rust stains down your siding.

- The Outvion Reality: Our UV-stabilized polycarbonate are “set and forget.” You might wipe it down with a damp cloth once a year to remove pollen. That’s it.

You are building this setup to relax, not to create another chore for yourself. The “savings” of a DIY project quickly vanish when you are spending your Saturday morning on a ladder with a paintbrush instead of watching the pre-game show. invest thousands in landscaping, patio furniture, and lighting, do you really want a plywood box to be the focal point?

Conclusion: Save Your Weekend, Save Your TV

There is a time and place for carpentry. If you want to build a beautiful harvest table for your patio, go for it. Wood is perfect for that.

But when it comes to protecting high-voltage electronics from rain, heat, and bugs, wood is simply the wrong tool for the job. The physics of insulation, the chemistry of moisture absorption, and the mechanics of weight all work against you.

Don’t risk destroying a $500 – 1,000 TV just to save $50 on a cabinet shell. Save your weekend for watching the game, not sawing lumber.

FAQ

1. Can I use Plexiglass for my DIY TV cabinet front?

No, and here is why. Standard acrylic (Plexiglass) is not UV stable. If you put it in direct sunlight, it will turn yellow and cloudy within 12 to 18 months. It also becomes brittle and can crack upon impact. Outvion uses optical-grade Polycarbonate that is co-extruded with UV stabilizers, ensuring it stays clear and shatterproof for years.

2. How many ventilation holes do I need for a DIY cabinet?

Passive holes are rarely enough. Even if you drill 20 holes, you are relying on hot air rising (convection). In a small, insulated wood box, the heat builds up faster than it rises. To safely cool a TV, you need active forced air—fans that physically push hot air out and pull cool air in, cycling the volume 3-4 times per minute.

3. Is pressure-treated wood safe for electronics?

Warning: Absolutely not. Pressure-treated lumber (the green stuff used for decks) is treated with chemicals like Alkaline Copper Quaternary (ACQ). These chemicals are corrosive to metals. If the high humidity inside the box transfers these chemicals to your TV’s circuit boards, it will corrode the copper traces and destroy the motherboard.

4. Can I paint my DIY cabinet to waterproof it?

Paint helps, but it is not a cure-all. Wood expands and contracts with humidity. Over time, this movement causes the paint film to crack—usually at the joints where two pieces of wood meet. Once that hairline crack opens, moisture enters the wood, gets trapped under the paint, and causes rot from the inside out.

5. What about using a plastic storage bin as a DIY case?

We see this “life hack” online often. Please don’t. Storage bins are made of cheap polyethylene. They are not UV stable; they will become brittle and crack after one season in the sun. They offer zero ventilation, turning into a greenhouse that will cook your TV in minutes. Plus, aesthetically, it looks terrible on your wall.

6. Will a wooden cabinet block my Wi-Fi?

Wood itself is relatively transparent to Wi-Fi. However, DIY cabinets often use thick 3/4″ walls, heavy metal hinges, and sometimes wire mesh for ventilation screens. This combination of density and metal can degrade the signal. Outvion’s thin polycarbonate shell is RF-transparent, allowing stronger signal penetration.

Recommended Technical Reading

- Wood Shrinkage & Expansion Database:The Wood Database

- See the Tangential and Radial shrinkage rates for different wood species.

- Thermal Management in Enclosures:Electronics Cooling Magazine

- Articles on “Natural vs. Forced Convection” in sealed electronics.

- Polycarbonate vs. Acrylic (Plexiglass):Curbell Plastics Material Guide

- Technical comparison of impact strength and UV resistance.